Welcome to Excel Sealing Solution since 2010

GST Certified: 27AWLPC3457G1ZI

Welcome to Excel Sealing Solution since 2010

GST Certified: 27AWLPC3457G1ZI

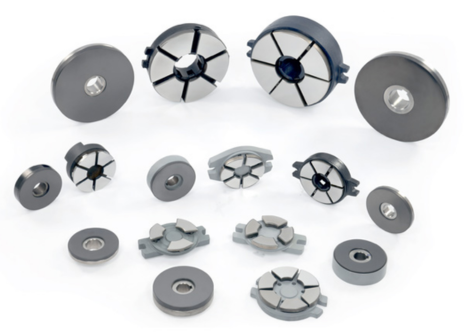

A carbon thrust bearing, also known as a carbon thrust pad or carbon thrust washer, is a type of bearing used to support axial loads (thrust) in rotating machinery. It is designed to handle the forces generated by axial movement between the rotating and stationary components and provide low-friction, reliable support to ensure smooth operation and reduce wear.

Carbon thrust bearings are typically made from a combination of carbon materials, such as carbon fibers and graphite particles, along with a binder or resin to form a solid and durable structure. The specific composition and design of the thrust bearing can vary based on the application and the load requirements.

In rotating machinery, such as pumps, turbines, or gearboxes, there is often axial movement between the rotating shaft and the stationary housing or casing. This axial movement generates thrust forces that need to be managed to avoid excessive wear and ensure the proper functioning of the machine.

The rotating surface is typically attached to the rotating shaft, while the stationary surface is mounted in the stationary housing. When axial loads are applied, the thrust bearing allows the surfaces to slide against each other with minimal friction, effectively supporting the axial forces.

The self-lubricating properties of the carbon material help reduce friction and wear, ensuring that the bearing can handle the axial loads over an extended period of operation without significant degradation.

Carbon thrust bearings are commonly used in various applications, including :

| Unit | WC.CO 6% | WC.CO 11% | WC.NI 6% | |

|---|---|---|---|---|

| Density | g/cm2 | 14.9 | 14.4 | 14.6 |

| Hardness HRA | kg/mm2 | 90.8 | 89.5 | 90.0 |

| Moduls of Elasticity | GPa | 600 | 570 | 610 |

| Fracture Strenght (MOR) | MPa | 1800 | 2400 | 1900 |

| Thermal Expansion (CTE) | 10-6/k | 4.5 | 4.8 | 5.0 |

| Thernal Conductivity | W/(m-k) | 84 | 82 | 96 |